Garment Printing 60cm Dtf Printer Shake Powder Machine XP600/I3200 Printhead

Basic Info.

| Model NO. | 60cm DTF |

| Structure | Platen Press |

| Color & Page | Single-Colour Printing Press |

| Usage | Paper Printer, Label Printer, Cloths Printer |

| Automatic Grade | Semi-Automatic |

| Printing Interface | USB3.0 |

| Printing Speed | 7.5CPI |

| System Supported | All System |

| Mother Board | Hoson Board |

| Gross Weight | 120kg |

| Headtype | XP600 |

| Printhead | I3200 |

| Transport Package | Wooden Box |

| Specification | 4 CBM |

| Trademark | union color |

| Origin | China |

| Production Capacity | 10000 |

Packaging & Delivery

Package Size 250.00cm * 100.00cm * 150.00cm Package Gross Weight 120.000kgProduct Description

Product Description

garment custom printing 60 cm DTF Machine printer with shake powder machine

Printer Function

Printer:

1.Epson original i3200-A1 print head, high speed, high resolution,durable.2.Constant tension paper feeding: to ensure that the white color is in place and accurate, and the paper does not run off when shaking.3.Front and rear platform heating, paper lack induction.4.Large ink bottle supplies ink, alarm for lack of ink.5.Integrated liting maintenance station, with timing flashing function, better maintenance of the nozzle.6.White ink ribbon circulation stirring Carmel stepper peristaltic pump, ink path and paper feeding system are controlled by PLC, and pressure control white ink, stable and continuous ink supply Industria-grade processing long beam, Japanese THK guide rail, integrated heavy-duty tripod.Powder spread and shaking equipment:

1.Preheating (temperature adjustable).2.The powder is removed by the brush, and the constant temperature of the powder box has dehumidification function.3.Quantitative dusting (the amount of powder is controlled by the weight sensor, and there are powder blocking devices on both sides to reduce artificial powder return.4.Flap-type powder removal, adjustable speed.5.Mesh belt transmission, adjustable speed, front and rear suction, simple and quick operation, up and down intelligent baking, PDI control, constant temperature, to ensure that the printing film does not change shape.6.Double-layer fan cooling device.7.Automatic paper delivery device, can choose to punch and cut or automatic paper delivery.8.Intelligent PLC touch screen control system, easy to operate, with alarm monitoring, extremely simplified operation.

Machine Specification

| Printer | shake powder machine | |

| Model | F9260 | WD20660-4 |

| Print Head Model | i3200-A1/2 original Epson i3200-A1 | |

| Printing Speed | High speed mode 15 m² /hour HD mode 10²/hour | |

| Color Mode | CMYK+W | |

| Print Format | 600mm | |

| Media Transfer | Damping paper/tension paper | |

| Heating Equipment | Front, middle and back three-stage heating | |

| Ink Road System | Automatic ink supply, white ink circulating and stirring | |

| Power Supply | 110V/220V 50-60HZ | |

| Power | 1.5KW | 5KW |

| working environment | 50- 70 phTemperature 20-28 C° Humidity 50-70ph | |

| Weight | 165kg | 160kg |

| Package Size | 203*100*134cm | 203*113*120cm |

| Cover an area | 1.8*3.5m | |

Printer Feature

1. Solving the picky problem of direct-injection printing fabrics, not limited to fabric transfer.

2. Don't worry about color deviation and fastness issues.3. No stroke, no cutting and waste discharge, one-key dot function.4. Short cycle and quick delivery time, breaking through the limitation of traditional process color-making plate making,digital output quick plate making, no need to wait for production, one piece of printing can be started at any operation.5. High cost-effective, without high invest funds of equipment and site,you can have an office and home-style clothing heat transfer factory.Detailed Photos

Production Process

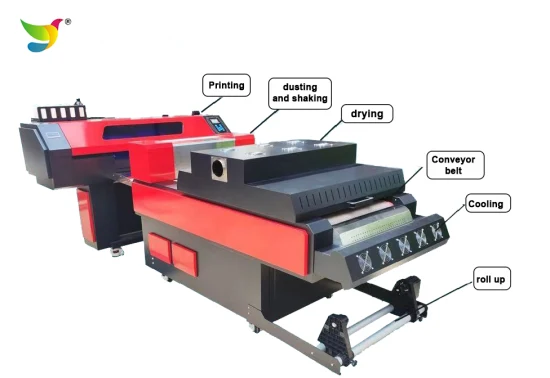

printing → dusting and shaking powder drying → pressing → finished product Supporting Supplies

water-based white ink water-based color ink Transfer PET film TPU hot melt powder

Our Service

1.Quality Assurance. the printer machine is new and original from factory.and have got certification with CE.

2.Online guidance.free training course will be provided to assist customers on installation and maintenance of the printer. include set up/use/repair.3.24 hourse service for you online.any problem about machine can be out forward,we are glad to help you for solving it.4.The main board have problem if within one year,please back and we will repair or change a new one for you.5.If necessary,our engineers will come to your place for repairing the machine.6.we do best service for every customer.please have a try.

Company Profile

Union Color (Guangzhou) Technology.Co.,Ltd was established in 1998,is the professional supplier that exports advertising equipments and consumables.All products are CE and ISO9001 certified, which is ensureof product quality.and sales regions have reached to Russia, Brazil, Malaysia, Singapore, Philippines, Thailand, VietNam,Turkey, Ecuador, Iran and other countries.

The core we deal with covers Infiniti, Phaeton,Crystaljet high resolution large format printers; Leopard,Infiniti UV flatbed printer;Galaxy,Allwin Eco-solvent printer. Solvent inks include: Seiko SK4,Crystaljet CJ35,Allwin Konica, Flora Polaris, Wit-Color Xaar etc;Lentll environmental Series inks,UV inks,Epson LED -UV curable inks; Eco-Solvent inks for i3200/Dx5/Xp600.We also is the distributor of FuJiang factory in Guangzhou.

Our Ink is suitable for:Infiniti, Crystaljet, Phaeton, GongZheng, Icontek, Allwin , Leopard , Flora, Wit-Color, etc.For the printhead such as:Seiko510/1020, Konica 512i/1024i, Polaris 512 etc. All series of ink before leaving factory have been tested by the corresponding model printer. Professionalclean production environment,multiple fine filtration process, the ink droplet finesse the nanometer level, toensure that the reduction degree of fluency and ink colors.

Packaging & Shipping