BOPP Pet Shrink Film Surface Gravure Printing Water Based Printing Ink

Package Size 32.50cm * 32.50cm * 36.00cm Package Gross Weight 21.000kg About Water Based Ink Water based ink is Made of

Basic Info.

| Model NO. | BY-4001 |

| Performance | Viscosity |

| Component | Varnish, Color Paste, Asistant Liquid |

| Drying Type | Quick Drying |

| Custom Sample | Available |

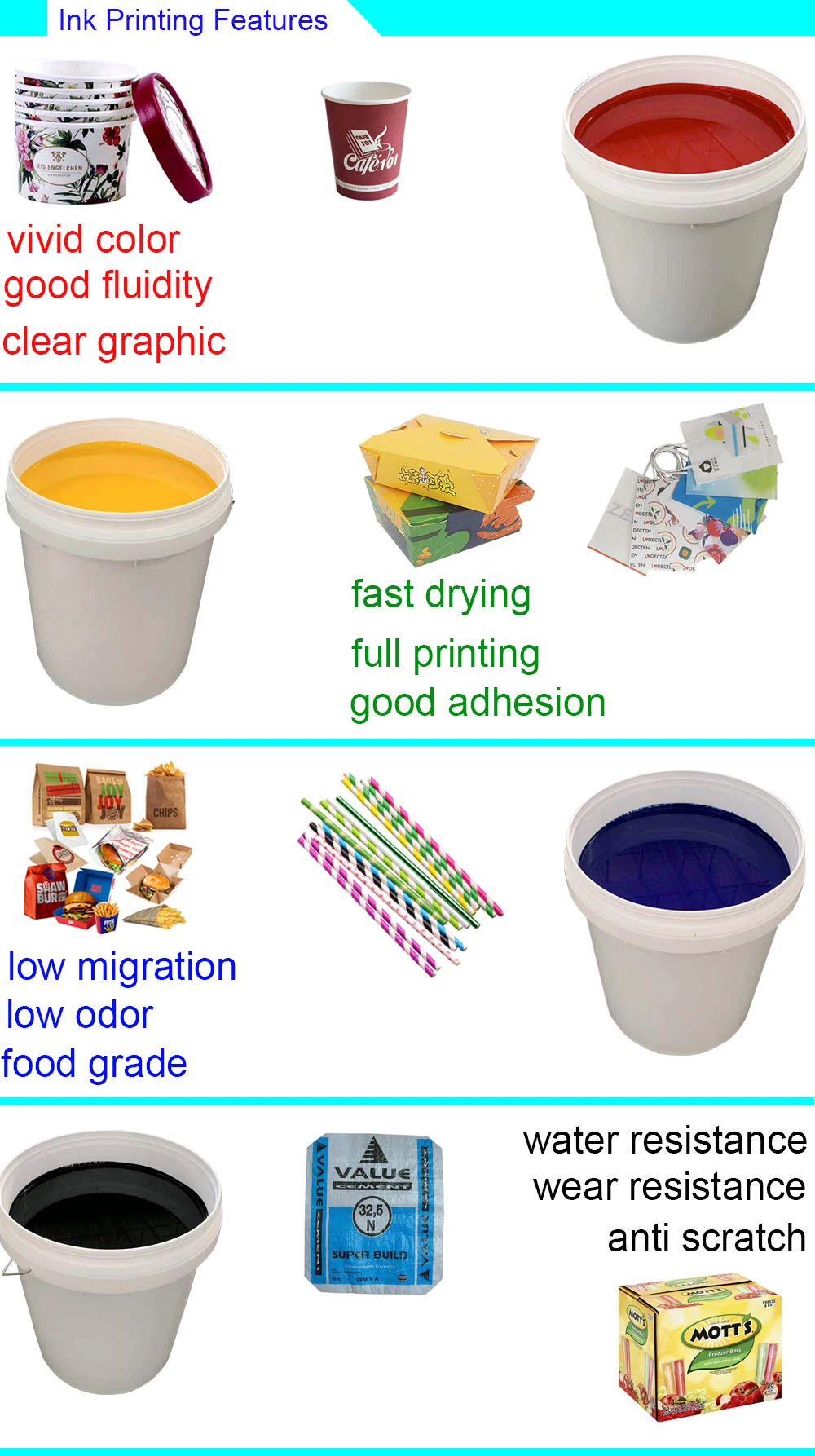

| Application | Paper Cup, Paper Bowl, Coffee Cup |

| Shelf Life | 2 Years |

| Density | High Color Density |

| Certificates | FDA, RoHS, LFGB, Reach |

| Feature | No Reverse Stick |

| Stock | Available |

| Deliver Time | Within One Week |

| Odor | A Grade |

| Features | Gravure Printing |

| Viscosity | 12-15 Seconds with 3# Zahn Cup |

| Waterproof | 0 Grade |

| Wear Resisitance | 0 Grade |

| pH Value | 8-9 |

| Transport Package | Barrel, Pallet |

| Specification | 10kg/barrel, 20kg/barrel, 200kg/barrel |

| Trademark | Oriental Colors |

| Origin | China |

| HS Code | 32159090 |

| Production Capacity | 700000 Kg/Month |

Packaging & Delivery

Package Size 32.50cm * 32.50cm * 36.00cm Package Gross Weight 21.000kgProduct Description

About Water Based InkWater based ink is Made of water-soluble resin, organic pigment, solvent and related auxiliaries by grinding and stirring. The solid content is 40~50% (pigmeng+resin). Suitable for the printing of food paper packaging, plastic shopping bag, thermal paper label,corrugated paper carton, non woven fabric bag, woven bag (heavy industrial bag), plastic film,PLA film, FFS film, medical paper packaging.Environmentally friendly( no pollution), health(no harm to human), safe(non flamable), economy(savenatural resource).

| Application Field | plastic vest bag, roll plastic bag, express bag, PE electronic product bag, biodegradable bag etc surface printing | |||

| Applied Substrate | polyethylene film, biodegradable (PLA) film and other film substrates | |||

| Machine Type | gravure machine, flexo machine | |||

| Product Parameter | Viscosity 3# zahn cup | PH Value | Fineness | Heat Resistance (ºC) |

| 12-16 | 8-9 | <5 | <230 | |

| Printing Parameter | Gravure Machine(Blowing film while printing | Printing Viscosity:10-13s/ZAHN3# cup;oven:ideal length1.4-2.5m;hot wind temperature:50-80ºC;suggested plate depth:25-35μm(colorful);35-45μm(white) The hardness of chrome plating is increased by more than 80;printing speed:20-60m/min | ||

| Gravure Machine Flexo Machine | Gravure, Flexo Printing :10-13S/ZAHN3# cup Printing Speed 30-200m/min;best 50-120m/min Flexo Printing anilox lines:200-600 lines. Suggested depth of Gravure Printing :25-35μm(colorful);35-45μm(white) | |||

| Packaging | 10kg/bucket, 20kg/bucket,1000kg/bucket | |||

| Using Instruction | Please stir evenly before using,keep the product ingredient consistent, test and adjust product pH value and viscosity, check color, keep the water based ink moving during using to prevent the ink from drying or plate blurring ·Printing substrate tension : surface tension of 38 dynes or more (some films need to be more than 40 dynes) ·Common auxiliary agent:PH stabilizer ;Defoamer ;fast drying agent | |||

| storage condition | 10-35ºC storaged in cool ventilated place, sealed, avoid fire, avoid rain | |||

| Shelf time | sealed, one year | |||

FAQ

Q1:How to avoid color difference?

A: Use new ink each time. Avoiding water adding, if it is needful, try to add little each time and mix evenly. Use the same substrate each time(the base color of the substrate will cause color difference. Maintain the printing press, anilox roller, andscraper in time; clean the ink box in time.Q2: Why there is odor from the ink?

A: Tap water will shorten the ink shelf time. It will deteriorate easier if too much tap water added. Stock the ink in sealed condition and in ventilated place.Q3: How to solve the edge fluffing problem?

A: In low printing speed, restart the press or tune the press until the scraping plate appears. In normal high speed printing, add slowing dry agent or stabilizer to solve the fluffing problem.Q4: What are the reasons for the printed words are too slim and not clear?

A: The printing is too slow but drying is fast, poor converting. Printing pressure is too big and the ink loading is too much.Q5: The printing drying condition is not good, what are the reasons?

A: The ambient temperature is too low; the humidity is too high;the power of the drying tunnel or infrared lamp is low. Substrate surface is too smooth, and the ink absorption deviate.Q6: The ink become thick after long storage, how can I reuse it?

A: Generally speaking, if stored in our suggested way, the ink will keep in good condition. It become thick because it is stored unsealed and the water volatilized. you can add some stabilizer and water, stir evenly and filter. Then you can use again.

Send to us